It’s a common saying that brewers are just glorified janitors. But, online advice from brewers is all over the map. Some chemical manufacturers promise a “one step” solution to cleaning and sanitizing, while others say that’s impossible. It’s hard to know what to believe. What’s properly clean? What’s the difference between sanitized, disinfected, and sterile?

Read on as we demystify cleaning and sanitizing your brewery equipment.

This article deals with the “cold side” of the brewery. The cold side is everything that touches your wort or beer after it leaves the kettle, including any ports and valves on the kettle and your transfer tubing. We will feature cleaning hot side equipment in a future article.

TL;DR: First You Clean; Then You Sanitize

In case you’re not going to make it through the article, the process is simple, first you must thoroughly clean, and only then can you effectively sanitize.

Why Do We Need to Clean or Sanitize at All?

After all, the ancients have been brewing beer for millennia before anyone had invented bleach or iodophor, right? It’s easy to dismiss them for being too stupid to recognize they were drinking sour and smoky beer. However, contemporary accounts tell us that our beer-guzzling forbears knew the difference between bad beer and good beer. Beer in ancient times was consumed far faster than it is today, before it spoiled. And as soon as making beer for distribution and export became a thing, beer spoilage became a major commercial issue.

In fact, beer spoilage was the principal thing that Louis Pasteur was investigating (beer was where the money was). Beer spoilage is the reason scientists identified yeast (and bacteria) and why they isolated pure cultures of yeast. As soon commercial brewers got the tools to deal with beer spoilage, they took measures to eliminate unwanted microbes from their breweries.

Home Brewing is Not Ancient Brewing

In a modern home brewery, if you do not properly clean and sanitize your equipment, you will eventually face microbial contamination. Contamination can result in spoiled beer, or in the worst case, bottle bombs. Winging it might be fine most of the time if you guzzle your beer in a week or two. However, most homebrewers plan to hold on to bottles or draft beer for several weeks, and in come cases months or years. Besides loss of the beer, that that means loss of money and the time you invested in a batch.

First, “You Can Only Sanitize Clean Equipment”

In our podcast episode with Emily Lovato of Five Star Chemical, Emily explained that you cannot sanitize equipment unless you clean it first. Dirty equipment will always contain bacteria.

Properly cleaning brewery equipment means removing all organic and inorganic deposits.

Organic Deposits

Organic deposits are things like yeast, trub and sediment, kraeusen — the hops and protein material that can get stuck to your fermentors, kegs, and other vessels — as well as older wort or beer. Being biological material, they can provide an ideal hiding place for microbes and even feed these unwanted “bugs”.

Some of the best cleaning products for home brewing are alkaline cleaners, especially sodium percarbonate-based cleaners. Each of these products contain a calculated formulation of functional chemicals. These functions include:

(a) An oxidizer: a type of detergent that breaks up organic material.

(b) A builder: a water softener that makes water “wetter” and makes the oxidizer work better

(c) A buffer: which maintains the high pH necessary for the oxidizer to work.

(d) A chelating agent aka sequestrant: this grabs onto metals like calcium that would otherwise form inorganic films on the surface.

Commercial examples include Five Star PBW, Craftmeister Alkaline Brewery Wash and Oxygen Brewery Wash, B-Brite, and One Step, and Easy Clean. Oxiclean Free Versatile Stain Remover powder is a household product that home brewers commonly use to clean their brewery, sometimes in a 70% combination with 30% TSP/90.

My analysis of material safety data sheets for all of these products indicates that only PBW covers all four functions, and may be among the most effective at both cleaning and minimizing beerstone formation. If you want to see my analysis about the active ingredients in cleaning products commonly marketed to home brewers, click the “Brewery Clening” link at this page on the Nordeast Brewers Alliance site (my “home” homebrew club) and see page three (credit for the other pages belongs to other club members).

A Note about Chlorinated Cleaners

While commercial brewers sometimes use chlorinated cleaners, they have standard operating procedures that are far more rigorous than most home brewers use. Unlike percarbonated cleaners like PBW or Easy Clean, chlorinated cleaners can lead to pitting of stainless steel equipment and chlorophenol off flavor. Because there are so many great cleaners available for home brewers, I recommend that home brewers leave these industrial, chlorinated cleaners to the pros.

Inorganic Deposits

Inorganic deposits mean beerstone (calcium oxalate) and lime scale (typically calcium carbonate). These “hard” deposits form a “stone” – a white, sometimes chalky film — on surfaces. Alkaline cleaners that do not contain a chelating agent can sometimes contribute to stone formation.

Inorganic films can also provide a hiding place for unwanted microbes and keep you from effectively killing them when sanitizing. What’s worse, stone can “starve” stainless steel of contact with the air, leading to a loss of passivation. This can eventually result in corrosion of the stainless steel.

While high pH, alkaline cleaners work best on organic matter, you need to go low pH with acidic cleaners to remove inorganic deposits. The acid will dissolve the stone and leave your surface pristine.

There are a few commercial brewery products available to home brewers, such as Acid No. 5 or 75% phosphoric acid. However, I have found that the farm supply is a great place to shop for acid cleaners. Milkstone is a major problem for dairy operations. Milkstone remover (phosphoric and nitric acids) is readily available at much lower prices than brewery products. Other options include making a DIY acid cleaning from citric acid, which is available online and in Asian grocers.

Inspect Your Equipment

After cleaning, be sure to inspect your equipment for the absence of organic and inorganic films and deposits. Inspect cleaned equipment both wet and dry because these films and deposits may be more visible on dry equipment. Use a flashlight or natural sunlight, and for transparent equipment use backlight to inspect adequately.

But a Product Promises Cleaning and Sanitizing in “One Step” …

Well, let me let Five Star Chemical explain: “Cleaners are not sanitizers, and sanitizers are not cleaners. Cleaning and sanitizing are not the same and should consist of two steps. Cleaners are designed to remove soils and sanitizers kill the bacteria. Don’t cut corners. There is not one solution for both.” If it could be done, I am sure the experts at Five Star, National Chemical, or Birko would have come up with a “one product to do it all” too. The ingredients show that One Step is similar to other cleaners. It’s worth noting that the maker of One Step has also produced an excellent sanitizer (San Step) to address the fact that One Step is not a sanitizer.

Nevertheless, it’s also true that many people have used One Step for years, most notably famed home brewer Josh Weikert, with few contamination issues. This goes along with the teaching of Charlie Talley. He says that if you start with a smooth, pristine surface and clean it properly, there isn’t anywhere for microbes to hide. Thus, the chances are the cleaner washed them off or damaged them. This is why Josh Weikert replaces all of his plastic extremely frequently and is therefore able to get away with using One Step exclusively.

Sanitizing vs Disinfecting vs Sterilization

So what is the difference between sanitizing, disinfecting, and sterilization? People use these terms interchangeably and it’s so confusing!

Brewers Sanitize; They Don’t Sterilize.

Well, let’s start by saying that outside of their yeast labs, brewers sanitize; they don’t sterilize.

Sanitizing

Sanitizing is a standard created by the U.S. Environmental Protection Agency, in conjunction with U.S. Department of Agriculture. The standard’s purpose is for food preparation and processing surfaces. The test is done on specific variants of E. Coli and Staphylococcus that are known as human pathogens,. It requires a sanitizer to perform as well as a chlorine bleach solution with two minutes contact time.

Sanitizing requires a 5-log kill rate for microbes (meaning that 99.999% of bacteria are killed, or only one in 105 survives). However, the sporule forms of any microbes will generally survive sanitization.

Humans have active immune systems. Beer has some protection from hops and your brewers yeast culture, but it is questionable whether the sanitization standard is completely applicable to the brewery industry. Nevertheless, popular sanitizers like iodophor, Star San, and quaternary ammonium sanitizers have served commercial and home brewers well over millions of batches.

Popular and effective sanitizers include BTF iodophor, Five Star Star San, LOGIC San Step, and (non-chlorinated) quaternary ammonium sanitizers available at restaurant suppliers.

————————————————————————————————————————–

The Log Scale – as you may remember from high school math, logarithms relate to exponents or the “power number” (like x to the power of y, or xy, where y is the exponent or power number). An increase of one in logarithms (or “one log”) is a ten-fold increase in numbers. For example 106 is 10x as much as 105. The log scale is used in many brewing applications, including in sanitizing and pH. For example, there is a difference of 1.0 units between pH of 4.5 and a pH of 3.5, and so a beer with pH of 3.5 is 10x more acidic than a beer with pH of 4.5.

————————————————————————————————————————–

Disinfection

Disinfection implies a 6-log kill rate for microbes (99.9999% are killed, or only one in 106 survives), but again their sporule forms can generally survive.

Examples of disinfection include chlorine or chloramine treatment of tap water and boiling silicone tubing or other equipment.

Sterilizing

Sterilizing uses a different measurement method than the log reduction calculation. It requires a sterility assurance level (SAL) of at least 106, typically. Simply, this means that there is a one in a million chance that ANY SINGLE non-sterile unit (microbe or spore) has survived. A SAL of 106 correlates to around a 12-log reduction in microbes, for comparison purposes. That’s means we are killing roughly 10 million times more microbes in sterilizing than the minimum threshold for sanitation!

Laboratories and hospitals typically use an autoclave to steam sterilize equipment with heat and pressure.

Testing for Sterilization

There are three common ways to test sterilization methods:

- Does the equipment work? The temperature and time needed to sterilize can be tested with placed in the autoclave or pressure cooker.

- The equipment works, but did it sterilize? The actual effectiveness of the sterilization can be tested by swabbing presumed-sterile surfaces and trying to grow microbes on an agar medium plate.

- Direct testing of sterilization: The effectiveness of the sterilization methods and equipment can be tested directly on microbes. Biological supply houses sell ampules of heat-resistant bacteria. These ampules are run through the sterilization process, and then whether any microbes or spores survived is tested with a color-changing dye.

Home Sterilization Methods

- Pressure Canner: You can use a pressure canner (as opposed to a regular pressure cooker) to sterilize like an autoclave if you set it at 15 psi and steam items for 30 minutes, not including steam release time. This achieves the required temperature of 250°F/121°C.

- Instant Pot: Wait, didn’t I just get done saying a regular pressure cooker is not good enough? There is a 2018 research study showing that a 6-quart Instant Pot is unique and is able to adequately sterilize items.

- Heat Sterilization in the Oven: You can effectively heat sterilize is clean glass and stainless steel items at 350°F/177°C for three hours. Exclude heating up and cooldown times. When heating glass, be sure to start the glass in the oven when it is cool and leave it until the oven is cool again to avoid embrittling the glass.

- Tyndallization: A fourth way to sterilize items is to boil it in water for 15 minutes every 24 hours, for three straight days. The boil kills most microbes. Then the subsequent boils kill any spores activated after the first or second boiling.

When to Sanitize, Disinfect, or Sterilize

Sterilize …

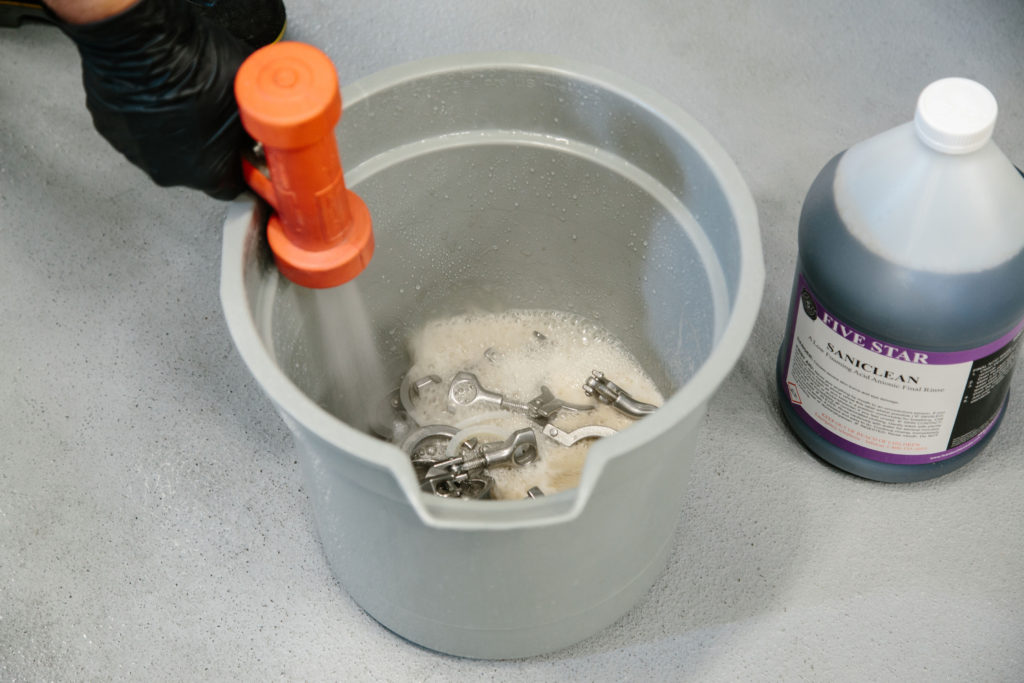

Equipment and growth media when yeast banking. And small parts such as disassembled ball valves, keg parts, hose barbs, other fittings, and silicone tubing when trying to eradicate a persistent contamination in the brewery.

Disinfect …

When you boil wort. But also you can boil small parts such as disassembled ball valves, keg parts, hose barbs, other fittings, and silicone tubing.

Sanitize …

All of your other cold side brewery equipment

A Final Tip on Using Cleaning and Sanitizing Chemicals

Well, let’s end this baby with another quote from Five Star: “Follow printed labeled instructions for time, temperature, and concentration. The labeled instructions are there for a reason and you should follow them.”

Come back to this site for future installments on (a) how to clean hot side equipment, and (b) pro tips on cleaning and sanitizing. Until then, happy sanitation!

Resources:

Birko’s Principles of Cleaning and Sanitation

Five Star’s Eight Rules of Cleaning and Sanitation